News in our goods

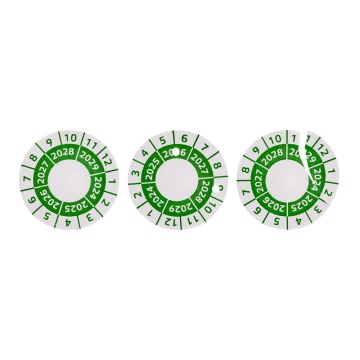

H733 Calibration sticker 2024, 2025, 2026, 2027, 2028, 2029 orange 12mm

H733 Calibration sticker 2024, 2025, 2026, 2027, 2028, 2029 orange 12mm

from 0.011 € / pc.

from 0.009 € without VAT

from 0.009 € without VAT

in Stock

400733

Product detail

H734 Calibration sticker 2024, 2025, 2026, 2027, 2028, 2029 green 20mm

H734 Calibration sticker 2024, 2025, 2026, 2027, 2028, 2029 green 20mm

from 0.019 € / pc.

from 0.015 € without VAT

from 0.015 € without VAT

in Stock

400734

Product detail

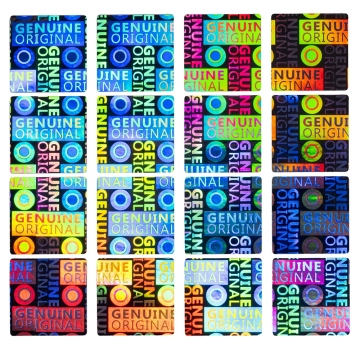

H732 Double layer square holographic residual VOID seal Original 23x23mm

H732 Double layer square holographic residual VOID seal Original 23x23mm

from 0.094 € / pc.

from 0.076 € without VAT

from 0.076 € without VAT

in Stock

400732

Product detail

H731 Non-residual white - translucent round VOID sticker with high adhesion 20mm

H731 Non-residual white - translucent round VOID sticker with high adhesion 20mm

from 0.064 € / pc.

from 0.052 € without VAT

from 0.052 € without VAT

in Stock

400731

Product detail

Where holograms are used

Products

- Holographic labels as certificates of ancestry

- Holographic „genuine“ labels – certificates of originality

- Self-adhesive stickers with a type of a product and series number identification

- Labeling the products with a company logo in holographic form

- Autodestructive guarantee seals

- Holographic labels of controlled quality output

- Labels showing exclusivity – winning prizes in different competitions

- Holographic labels in the form of medals – e.g. for medal awarded wines

- Holographic self-adhesive stickers in the form of medals for the products awarded in competitions will draw attention of potentional customers and raise the market- price of the product

- Golden or silver medals can be paste to the products themselves and also documents connected with this product

Security

- hologram as a self-adhesive uncopiable security stickers useful anywhere it can be sticked

- universal standard for a higher visual security of exposed commodities which are highly likely falsified, copied or misused

- Holographic technologies of production of security self-adhesive labels outclass the progenitors – seals on the papers, imprints,duty stamps, trademarks, etc - in every aspect

- preventing the cargo from unauthorized manipulation with a seal / an imprint

- preventing the goods vehicles, containers, doors of cargo fields of the airplanes etc from unauthorized openning

- seal up the locks of road tankers

- sealing of transport boxes in air transportantion and prevent them from unauthorized penetration

- holographic sealing of gasmeters, flowmeters and electrometers

- sealing up the moneyboxes of ATMs

Civil service

- holographic labelling of ID cards of all civil service officers that come to contact with the public – inspectors, police officers, social workers

- securing the voting urns and voting tickets – sealing with a holographic label

- custom production of personnel labels for the assets

- seals for sealing the doors and areas when there is a police investigation

- a proof of authenticity of allowances or statements that were publicated by the state or the self-government (a town, a village)

- distribution of parking tickets with unfalsifiable logo of a town or its part

- holographic version of a permission to enter the state institutions –the label can be big or it can even be a whole card of permission to enter for easier recognition

- cards and ID cards allowing the entry to to state institutions and offices

- Holographic labels for marking the annual or monthly validity of ID cards

Quality

- Holographic label of quality for custom made products gives the customer necessary assurance about the origin and quality of the product

- Seal of the outcome control quality is not just an information about the previously done inspection but at the same time can be a security label confirming the origin of the product

- Holographic form of quality seals are mostly desirable by the expensive commodities for investment purpose - gold, coins and medals

- Even application of the simple labels “Quality Control Passed“ can add to the exceptionality of the labeled product thanks to the customer’s graphics in the holo layer

- Every controlee of the outcome control can use the labels with different numbers or there might be a different number responding to the number in the protocol of the control on each seal

- Certificate Of Conformity – labels professing the proclamation about conformity

Entrance tickets

- self-adhesive hologram adds the visual authenticity, credibility and makes the controlling of any entrance ticket easier

- unique attention and prevention from falsifying goes to the permanent entrance tickets (season-tickets) – hologram secures the tickets and allows them to be repeatedly used for an entry

- using the holographic emblem on the entrance tickets, tickets or transport tickets contributes to the trustworthiness of the seller, even if the tickets are sold secondhand

- appropriation of using the holographic label increases with significance of the organized event, at VIP tickets its a guarantee of exclusivity

- protection of tickets printed on plain paper, such as ball tickets printed on a laser printer

- secure tickets for balls against copying

Contracts

- self-adhesive hologram represents a unique form of „signature“ on important documents such as contracts, decretums, allowances, protocols, enrollments etc.

- you can choose a degree of impossibility of falsifying and criterion of costs for securing acccording to importance of the documents using the holographic self-adhesive stickers with different types of security items

- for securing of papers and documents you can either use direct sticking of the label or sticking the holographing label on the edges of the papers in case of a document with more pages attached to one another

- there is no possibility of unsticking the holographic label from the document and sticking it to another one – there is always a visible damage done to the label

ID cards

- the cheaper way to label the ID cards with a hologram - mostly for smaller series - is to stick a non-sealable sticker on them instead of printing the holograms

- the series number can be labeled directly in one of the holo layers of the security self-adhesive sticker, for other cards in the series it will be automatically incremented

- prevention from falsifying the staff cards allowing to enter the buildings

- holographic identifying and securing item can be easily applied on every card, ticket, club card, member card, meal ticket ,etc. by simple sticking

Certificates

- raising the prestige of editing certificates with a holographic logo

- securing that the study certificates used for academic titles will not be falsified

- certificates proving the graduation from a traning with the hologram as a decorative and safety item

Vouchers

- hologram is an accessible form of preventing the gift vouchers from falsifying

- by a self-adhesive stamp you can easily secure any voucher for a demand of anything, even if it was printed by an ordinary printer

- preventing the vouchers from falsifying – vouchers for an accomodation, catering, covering of services etc

- accessible and effective form of preventing the meal tickets from falsifyingk

- gift vouchers protection against counterfeiting

- defense against counterfeiting of tickets and vouchers hologram applications

Calibrations

- labelling of calibration letters by an immutable holographic motive

- dotting of calibrated products and measurements by an unfalsifiable holographic label

- sealing the access to regulating and calibrating parts of appliances

- holographic calibration seals will contain the customer’s company logo of a concrete calibration laboratory

Licenses

- licence holographic labels on data carriers

- unique hologram for the paper licenced certificates approving autheticity

- holographic security label on a box with software

- „Genuine“ and „Proof of Licence“ labels for proving the authenticity of installation CD

- labeling the documents approving the authorization for selling the products of a brand – selling licences

- COA (Certificate Of Authenticity) - holographic licence labels

Parking tickets

- unique holographic schema made according to your design prevents all kinds of parking tickets from falsifying and misusing

- to parking allowances we also include an allowance to otherwise forbidden places, here we can also apply holographic technologies of a visual security

- parking allowances can be under security items where every item would have its own identity number for maximal prevention from misuse or imitation